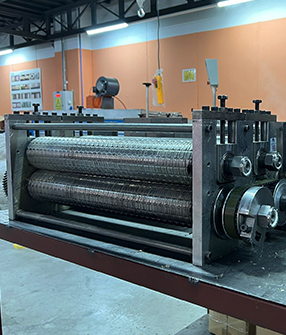

Rotation Cylinder Sets

Rotation Cylinder Sets: Precise and Efficient Turning Solutions

Rotation Cylinder Sets are mechanical systems that enable the precise and efficient execution of rotational movement in production processes. These sets play a critical role, especially in fields like printing, laminating, coating, and metalworking.

Advantages of Rotation Cylinder Sets

- Precise Rotation Motion: Ensures the cylinders rotate evenly and accurately.

- Durability: Long-lasting performance with high-quality materials.

- Versatile Use: Adaptable to different production lines.

- Efficiency: Optimizes the production process with continuous operation.

What Products are Manufactured?

Rotation Cylinder Sets are used in the production of a wide range of products across various industries:

- Laminated Products: Coating of paper and plastic surfaces.

- Printing Materials: For precise printing applications.

- Coating Materials: Coating of metal or plastic surfaces.

- Industrial Rollers: Custom rollers for filters and mechanical parts.

Applications

Rotation Cylinder Sets play a critical role in various industries:

- Printing Industry: Precision paper handling and printing processes in printing presses.

- Lamination and Coating: Coating processes on paper and metal surfaces.

- Industrial Production: Processing and transporting mechanical parts.

- Filter Manufacturing: Precision folding and material transport processes.

Why Choose Rotation Cylinder Sets?

- High Precision: Ensures accurate and consistent rotational motion.

- Durability and Reliability: Long-lasting materials and design.

- Flexibility: Compatible with various production lines.

- Efficiency: Saves time by optimizing the production process.