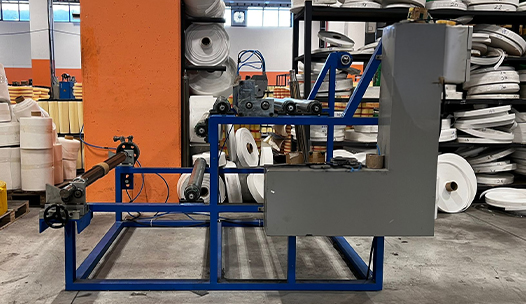

Coil Paper Cutting Machine

Paper Roll Cutting Machine: Fast and Precise Cutting Technology

Paper Roll Cutting Machine is an equipment that cuts large-sized paper rolls into desired dimensions, making them ready for use in filter production and other industrial applications. It is widely used in sectors such as automotive, industrial production, and packaging.

Advantages of Paper Roll Cutting Machine

- Precise Cutting: Cuts paper rolls into equal and accurate dimensions.

- High Speed: Fast processing capacity suitable for mass production.

- Versatile Material Support: Compatible with different types of filter papers and packaging materials.

- Waste Reduction: Offers cost advantages by minimizing material loss.

What Products are Produced?

The Paper Roll Cutting Machine provides a fundamental process for a wide range of products:

- Filter Papers: Papers used in air, oil, and pollen filters.

- Packaging Materials: Papers in custom sizes for the packaging industry.

- Industrial Papers: Processed paper types in various sizes and thicknesses.

Applications

This machine holds a significant place in the cutting and preparation processes across many sectors:

- Automotive Sector: Cutting and processing of vehicle filter papers.

- Industrial Filtration: Paper preparation for large-scale productions.

- Packaging Sector: Production of custom-sized packaging papers.

- Stationery and Printing: Precise sizing of paper rolls.

Why Choose a Paper Roll Cutting Machine?

- Precise and Flexible Cutting: Cutting options for different sizes and shapes.

- Efficiency: Design optimized for mass production processes.

- Material Savings: Economical production by minimizing waste.

- Long-Lasting Structure: Robust mechanical design with low maintenance needs.