Paper Gluing Machine

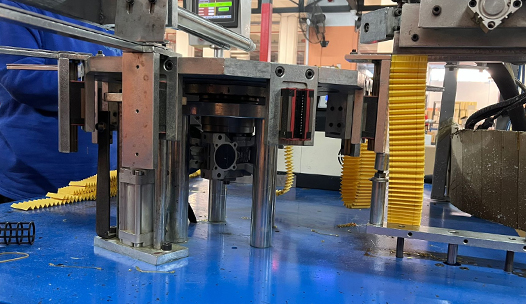

Paper Laminating Machine: Powerful and Precise Solutions for Filter Production

Paper Laminating Machine is a high-precision production equipment used to join and seal paper sheets in filter production. This machine plays a critical role in sectors such as automotive, industrial filtration, and ventilation.

Advantages of Paper Laminating Machine

- Precise Lamination: Ensures flawless bonding of filter papers.

- High Production Speed: Performance suitable for mass production needs.

- Material Compatibility: Can work with various types of filter paper.

- Durable Connections: Creates long-lasting and leak-proof structures.

What Products are Produced?

The Paper Laminating Machine is used in the production of the following products:

- Air Filters: Durable filters used in vehicles and industrial systems.

- Pollen Filters: Filters that improve cabin air quality.

- Industrial Dust Filters: Filters used for dust control in factories.

Applications

This machine plays a significant role in the production of paper-based filters in many sectors:

- Automotive Sector: Production of engine and cabin filters.

- Industrial Filtration: Durable filter materials used in factories.

- HVAC Systems: For commercial and residential ventilation systems.

Why Choose a Paper Laminating Machine?

- Precision and Quality: Joins paper sheets accurately and durably.

- Efficiency: Design suitable for mass production, enabling fast production.

- Flexibility: Compatible with different types of filter paper.

- Material Savings: Offers economical solutions with minimal adhesive usage.