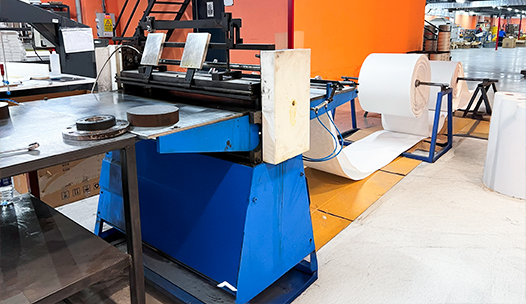

Pollen Filter Production Line

Pollen Filter Production Line: Precision and Efficient Production Solution

Pollen Filter Production Line is a modern production system that enables the automatic and highly precise production of pollen filters, which improve cabin air quality. It is commonly preferred in the automotive, ventilation, and air conditioning sectors.

Advantages of Pollen Filter Production Line

- Full Automation: Optimizes the production process and provides error-free operations.

- Precision: Ensures filters are produced to standard dimensions and high quality.

- High Efficiency: Designed for mass production capacity.

- Flexibility: Adapts to the production of different types and sizes of pollen filters.

Which Products are Produced?

Pollen Filter Production Line is used in the production of the following products:

- Pollen Filters: Filters that improve air quality inside the cabin.

- Air Filters: Filters that block dust and harmful particles.

- Industrial Filters: Filters used for large-scale ventilation systems.

Areas of Use

This production line is a critical tool for high-precision filter production in various sectors:

- Automotive Industry: Production of in-vehicle air filters.

- Ventilation Systems: Pollen filters for offices and homes.

- Industrial Filtration: For factories and production facilities.

Why Choose Pollen Filter Production Line?

- Precise Manufacturing: High quality and standard dimensions in products.

- Efficient Processes: Fast processing capacity suitable for mass production.

- Durable Design: Long-lasting with low maintenance cost.

- Flexible Solutions: Adaptable to different filter types.